We have spring / hydro cone crusher for sale, full models for choice, meeting your different needs.

Adjustable final size to meet your different needs

If you are interested in our products, please email us at inquiryhxjq@hxjq.com

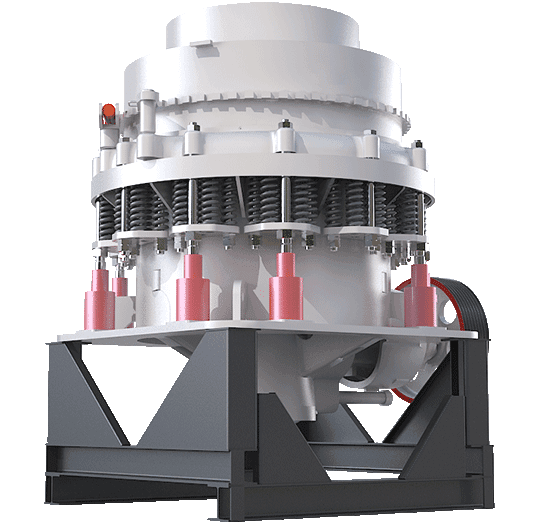

Cone crusher is usually used for processing the hard stones and ores with medium and large production scale. With unique structure, it has large processing capacity.

The safety spring system adopts the overload protection device, which makes foreign materials go through the crushing chamber without bringing damage to the machine. The sealing modes are dry oil or water, guaranteeing the reliable production.

Cone crusher is used for crushing over 100 kinds of hard stones and ores. It can be used for primary seconday fine crushing of minerals. Spring cone crusher, hydro cone crusher for sale.

1.For granite, quarry stones, rocks, aggregate, basalt, limestone, gold ore, iron ore, etc.

2.Common final output size:0-10mm, 10-20mm, 20-30mm, 30-40mm, etc.

3.Hot sale capacity:20-50t/h, 60-100t/h, 150-200t/h, 200-300t/h, 300-400t/h, etc.

1.Factory-direct sale, guaranteed quality with competitive price, saving costs.

2.High crushing efficiency, adjustable final size, reliable performance, easy maintenance.

3.High quality spare parts, long lifetime, full service system.

Free Inquiry

Online response

Customized solution

fast delivery

Cargo arrival

After-sales service

200t/h Stone Crusher Plant in Ethiopia

200t/h Stone Crusher Plant in Ethiopia

Cone Crusher

Full Hydraulic Cone Crusher

Multi-cylinder Hydraulic Cone Crusher

Single-cylinder Hydraulic Cone Crusher

| Type | Model | Max.feeding size(mm) | Adjusting Range of Discharge Opening(mm) | Processing capacity(t/h) | Main motor power(kw) |

| PSG 1300 | 1313 | 110 | 13-31 | 109-181 | 160 |

| 1321 | 170 | 16-38 | 132-253 | ||

| 1324 | 190 | 19-51 | 172-349 | ||

| 1306 | 50 | 3-16 | 36-163 | ||

| 1308 | 70 | 6-16 | 82-163 | ||

| 1310 | 85 | 8-25 | 109-227 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Cavities | Max.feeding Size(mm) | Adjusting Range of Discharge Opening(mm) | Processing capacity(t/h) | Power(kw) |

| GYS 300 | C1 | 140 | 13-38 | 81-180 | 90 |

| C2 | 80 | 9-22 | 60-180 | ||

| F1 | 60 | 3-16 | 36-145 | ||

| GYS 400 | C1 | 190 | 19-51 | 207-400 | 200 |

| C2 | 168 | 16-38 | 162-350 | ||

| F1 | 85 | 8-25 | 109-230 | ||

| F2 | 70 | 6-16 | 82-230 | ||

| GYS 500 | C1 | 215 | 25-64 | 280-650 | 280 |

| C3 | 170 | 16-38 | 180-410 | ||

| F1 | 105 | 10-25 | 162-355 | ||

| F3 | 55 | 5-13 | 90-300 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Cavities | Maximum Feeding size(mm) | Adjusting Range of Discharge port(mm) | Capacity(t/h) | Power(kw) |

| HPM200 | C1 | 145 | 22 | 160~250 | 160 |

| C2 | 100 | 18 | 145~250 | ||

| C3 | 75 | 14 | 120~250 | ||

| F1 | 60 | 12 | 108~210 | ||

| F2 | 45 | 10 | 81~210 | ||

| HPM300 | C1 | 190 | 26 | 230~445 | 220 |

| C2 | 170 | 20 | 200~445 | ||

| C3 | 120 | 16 | 180~445 | ||

| C4 | 85 | 14 | 160~220 | ||

| F1 | 40 | 12 | 140~220 | ||

| HPM400 | C1 | 240 | 35 | 270~630 | 315 |

| C2 | 200 | 25 | 252~630 | ||

| C3 | 160 | 25 | 243~630 | ||

| C4 | 190 | 18 | 210~630 | ||

| F1 | 75 | 15 | 162~370 | ||

| F2 | 40 | 13 | 126~370 | ||

| HPM500 | C1 | 270 | 38 | 365~790 | 400 |

| C2 | 230 | 30 | 328~790 | ||

| C3 | 165 | 22 | 280~790 | ||

| C4 | 105 | 20 | 202~450 | ||

| F1 | 75 | 16 | 175~450 | ||

| F2 | 42 | 8 | 158~450 | ||

| HPM650 | C1 | 262 | 30 | 386~790 | 500 |

| C2 | 225 | 25 | 348~790 | ||

| C3 | 175 | 20 | 300~790 | ||

| F1 | 85 | 13 | 280~530 | ||

| F2 | 42 | 9 | 220~530 | ||

| HPM800 | C1 | 280 | 38 | 616~1100 | 630 |

| C2 | 240 | 38 | 522~1100 | ||

| C3 | 214 | 25 | 495~1100 | ||

| C4 | 175 | 22 | 380~1100 | ||

| F1 | 125 | 20 | 328~730 | ||

| F2 | 75 | 16 | 270~730 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

SC Single Cylinder Cone Crusher Medium Crushing Series

| Model | Cavities | Maximum Feeding Size (mm) | Minimum Discharging Size (mm) | Capacity(t/h) |

| SC100S | C1 | 175 | 22 | 85-170 |

| C2 | 160 | 19 | 70-130 | |

| SC160S | C1 | 290 | 25 | 125-345 |

| C2 | 240 | 22 | 108-305 | |

| SC250S | C1 | 360 | 35 | 265-524 |

| C2 | 320 | 29 | 225-448 | |

| SC315S | C1 | 450 | 41 | 349-1050 |

| C2 | 400 | 38 | 318-892 | |

| SC450S | C1 | 480 | 44 | 498-1500 |

| C2 | 385 | 41 | 454-1274 |

SC Single Cylinder Cone Crusher Fine Crushing Series

| Model | Cavities | Maximum Feeding Size (mm) | Minimum Discharging Size (mm) | Capacity(t/h) |

| SC100 | F1 | 120 | 10 | 45-135 |

| F2 | 70 | 10 | 43-118 | |

| F3 | 40 | 6 | 25-40 | |

| SC160 | F1 | 160 | 13 | 69-215 |

| F2 | 90 | 10 | 57-184 | |

| F3 | 60 | 8 | 70-90 | |

| SC250 | F1 | 190 | 16 | 116-396 |

| F2 | 110 | 13 | 97-346 | |

| F3 | 55 | 9 | 90-251 | |

| SC315 | F1 | 220 | 32 | 177-662 |

| F2 | 170 | 29 | 209-643 | |

| F3 | 140 | 29 | 162-552 | |

| F4 | 70 | 19 | 175-325 | |

| SC560 | F1 | 240 | 22 | 448-1512 |

| F2 | 155 | 19 | 380-1373 | |

| F3 | 70 | 13 | 357-912 | |

| SC750 | F1 | 295 | 25 | 394-2181 |

| F2 | 240 | 19 | 342-2020 | |

| F3 | 185 | 16 | 267-1814 | |

| F4 | 95 | 13 | 248-1165 | |

| F5 | 70 | 10 | 185-1170 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

Large and medium-sized digital processing equipment

Leading manufacturer and exporter with 40 yrs history

Professional after-sale service personnel

Our Company is based in central China’s provincial capital city of Zheng Zhou, covering an area of 350,000 square meters. It occupies 260,000 square meters of standardized heavy-duty industrial workshop and possesses a variety of medium and large-sized metal processing and riveting machinery with more than 600 sets of assembly equipment.

Please leave us a message by filling up the form below or email us to inquiryhxjq@hxjq.com, let us know your requirements, we’ll send you tailored catalogue and price list within 24 hours. Thanks for your interest in China HXJQ.