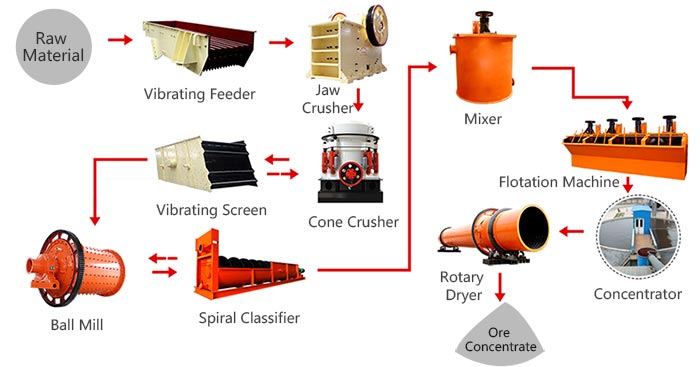

Flotation Separation Production Line

Production Capacity:1-280t/h

Final Output Size

-

0-10mm

0-10mm

-

10-20mm

10-20mm

-

20-40mm

20-40mm